The Ford Hydro-Boost System uses hydraulic pressure from the power steering pump to enhance braking performance. Operating between 1,200 to 1,500 psi, it boosts braking force, especially during heavy braking. Common issues include low fluid, leaks, and pressure-related damage, requiring regular maintenance for optimal performance.

Stay tuned with us as we dive deeper into the Ford Hydro-Boost System. We’ll explore its operating pressure, the key benefits, and highlight the common issues you might face. Don’t miss out on our detailed breakdown to keep your braking system running smoothly!

What Is The Typical Operating Pressure Of The Hydro-Boost System?

The typical operating pressure for a Ford Hydroboost system is around 1,500 to 2,500 psi. This pressure is generated by the power steering pump and is used to assist the braking system by multiplying the force applied to the brake pedal, making it easier to stop the vehicle. During normal braking, the pressure may range from 450 to 600 psi, but it can increase significantly under heavy braking or high-demand situations.

How Does The Hydro-Boost System Generate Braking Pressure?

The Hydroboost system generates braking pressure using hydraulic fluid from the power steering pump instead of relying on engine vacuum. Here’s how it works in simple terms:

- Pressing the Brake Pedal: When you press the brake pedal, it moves a lever inside the Hydroboost unit.

- Activating the Spool Valve: This lever opens a valve (called a spool valve) that allows pressurized hydraulic fluid from the power steering pump to flow into the Hydroboost unit.

- Creating Pressure: The hydraulic fluid enters a chamber inside the Hydroboost, where it pushes against a piston.

- Assisting the Brakes: This piston then pushes on the master cylinder, which is responsible for sending brake fluid to the brakes at each wheel. This action helps apply more force to the brakes than you could do with just your foot alone.

- Smooth Operation: The system is designed to work smoothly, so you don’t feel any strange feedback in the brake pedal when you use it.

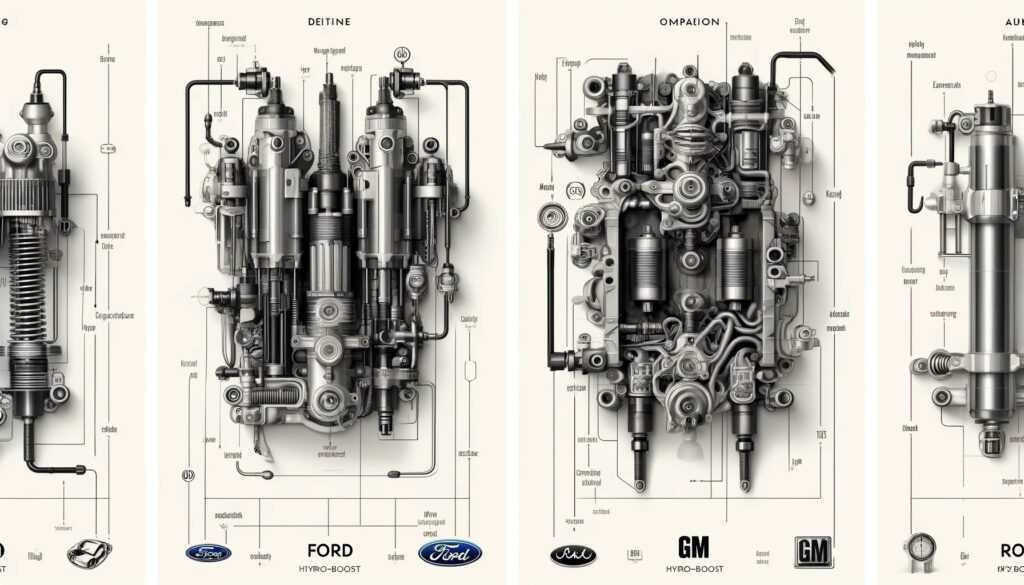

Are There Design Differences Between Ford And Gm Hydro-Boost Systems?

There are several design differences between Ford and GM Hydro-Boost systems, primarily related to their construction, mounting, and functionality. Here’s a simple breakdown of these differences:

Mounting and Size

- Ford Hydro-Boost: The Ford Hydro-Boost units are often designed to fit specific models and may have unique mounting brackets that align with Ford’s vehicle architecture. They can be more compact, making them suitable for tight engine compartments.

- GM Hydro-Boost: GM units might have a different mounting configuration and can vary significantly across different models. They may be larger or have different shapes that affect how they fit in various vehicles.

Hydraulic Connections

- Ford Systems: Typically, Ford Hydro-Boost systems have specific hose fittings and routing for hydraulic fluid that may differ from GM systems. This can affect how they connect to the power steering pump and the brake master cylinder.

- GM Systems: GM Hydro-Boost units may feature additional return ports for hydraulic fluid, which can help manage fluid flow more efficiently in some configurations.

Performance Characteristics

- Pressure and Valving: While both systems operate using hydraulic pressure, there might be variations in how they handle pressure and the internal valving design. This can lead to differences in braking feel and responsiveness.

- Hydraulic Fluid Flow: The design of the pumps used with each system can also differ, affecting how much hydraulic fluid is available for boosting brake pressure. This might make one system feel more responsive than the other under certain conditions.

Component Compatibility

Interchangeability: Generally, components from Ford Hydro-Boost systems are not interchangeable with GM systems due to differences in design specifications. This means that if you’re upgrading or replacing parts, you need to ensure compatibility with your specific vehicle brand.

Application Versatility

Both Ford and GM Hydro-Boost systems have been used in various applications, including trucks and performance vehicles, but the specific designs may cater to different performance needs based on the manufacturer’s goals for their vehicles.

What Is The Role Of The Low-Pressure (Return) Side In A Hydro-Boost System?

The low-pressure (return) side in a Hydro-Boost system plays a crucial role in ensuring that the system operates effectively. Here’s a simple explanation of its function:

- Return of Fluid: After the Hydro-Boost unit uses hydraulic fluid to help with braking, that fluid needs to go back to the power steering reservoir. The low-pressure side is responsible for returning this fluid.

- Pressure Levels: The pressure on the return side is very low, typically just a few psi. This means that the fluid is not under high pressure when it comes back, making it safe and easy for the system to handle.

- Preventing Back Pressure: It’s important that the return line is separate from other systems (like the power steering) to avoid any back pressure. If there’s back pressure, it could interfere with how well the Hydro-Boost unit works, potentially causing braking issues.

- Maintaining System Balance: By returning the used fluid to the reservoir, the low-pressure side helps maintain a balance in the hydraulic system, ensuring that there’s always enough fluid available for both steering and braking functions.

Can Excessive Pressure Damage The Hydro-Boost System?

Yes, too much pressure can harm the Hydro-Boost system. If the power steering pump creates more pressure than the system can handle, it can cause parts to wear out faster, develop leaks, or even stop working completely. To avoid this, it’s important to make sure the pump and Hydro-Boost system are compatible and installed correctly.

Can Using A Higher-Flow Power Steering Pump Affect Hydro-Boost Performance?

Using a higher-flow power steering pump can indeed affect the performance of a Hydro-Boost system. Here’s a simple breakdown of how this works:

More Fluid Flow:

A higher-flow pump sends more hydraulic fluid to the Hydro-Boost system. This can be beneficial because it allows the brakes to respond more quickly and with greater force.

Potential Overboosting:

However, if the flow is too high, it can lead to overboosting. This means that the brakes might feel too sensitive or grabby, making it harder to control the braking force smoothly. Drivers may find it difficult to apply just the right amount of pressure.

Steering Sensitivity:

Additionally, if the power steering pump provides too much flow, it can make the steering feel overly responsive or “twitchy.” This can be uncomfortable and reduce feedback from the steering wheel.

Compatibility Issues:

It’s important to match the flow rate of the pump with what the Hydro-Boost system needs. If the pump delivers too much flow, adjustments may be necessary, such as changing flow valves or using a different pump that better suits your setup.

Balancing Performance:

The key is to find a balance where the Hydro-Boost system gets enough hydraulic fluid for effective braking without overwhelming it, ensuring both braking and steering feel comfortable and responsive.

How Does The Hydro-Boost System Compare To Traditional Vacuum Boosters?

Hydro-Boost and traditional vacuum boosters are two different systems used to help with braking in vehicles. Here’s a simple comparison of the two:

How They Work

- Hydro-Boost: This system uses hydraulic pressure from the power steering pump to assist with braking. When you press the brake pedal, hydraulic fluid helps push the brake master cylinder, making it easier to stop the vehicle.

- Vacuum Booster: This system relies on vacuum pressure created by the engine. When you press the brake pedal, the vacuum helps pull a diaphragm that amplifies the force on the master cylinder, increasing braking power.

Key Differences

- Hydro-Boost uses hydraulic fluid, providing strong and consistent braking, even at high engine speeds or when engine vacuum is low. Vacuum boosters, on the other hand, depend on engine vacuum, which can drop at high RPMs or heavy acceleration, reducing braking power.

- Hydro-Boost systems generally offer better braking performance, especially for heavy-duty applications like towing or vehicles with high-performance engines. Vacuum boosters may struggle in situations where engine vacuum is insufficient, resulting in weaker braking.

- Hydro-Boost units are more compact, making them easier to fit into tighter spaces under the hood. Vacuum boosters are larger and may require more space for installation.

- Hydro-Boost systems are more complex and may need more maintenance due to their reliance on hydraulic components. Vacuum boosters are simpler and easier to maintain, but they can suffer from issues like vacuum leaks.

- Hydro-Boost systems are typically more expensive both to purchase and install. Vacuum boosters are generally cheaper and more affordable when it comes to repairs or replacements.

What Are The Safety Requirements For Working With Hydro-Boost Systems?

When working with Hydro-Boost systems, which use high-pressure hydraulic fluid, it’s important to follow safety guidelines to avoid accidents or damage:

Use strong hoses:

The hoses that carry the hydraulic fluid should be able to handle very high pressure (at least 12,750 psi). These hoses are specially made to prevent bursting or leaking.

Ensure proper installation:

All parts of the Hydro-Boost system, including the hoses, the pump, and the unit itself, must be installed correctly. If anything is loose or not connected properly, it can cause leaks or malfunctions.

Handle with care:

Since the system uses high-pressure fluid, it’s important to be careful when working with it. If you don’t handle it properly, the fluid can spray out, which could cause injury or damage to parts of the car.

How Can I Maintain The Hydro-Boost System For Optimal Performance?

Check for fluid leaks:

Regularly inspect the power steering lines and the Hydro-Boost unit for any leaks. Leaking fluid can lower performance or cause damage.

Monitor the power steering pump:

Make sure the power steering pump is working correctly and within the right pressure range. If it’s not, it can affect braking performance.

Replace damaged hoses:

The high-pressure hoses carry fluid to and from the Hydro-Boost unit. If you notice any cracks or wear, replace them to prevent fluid loss or damage.

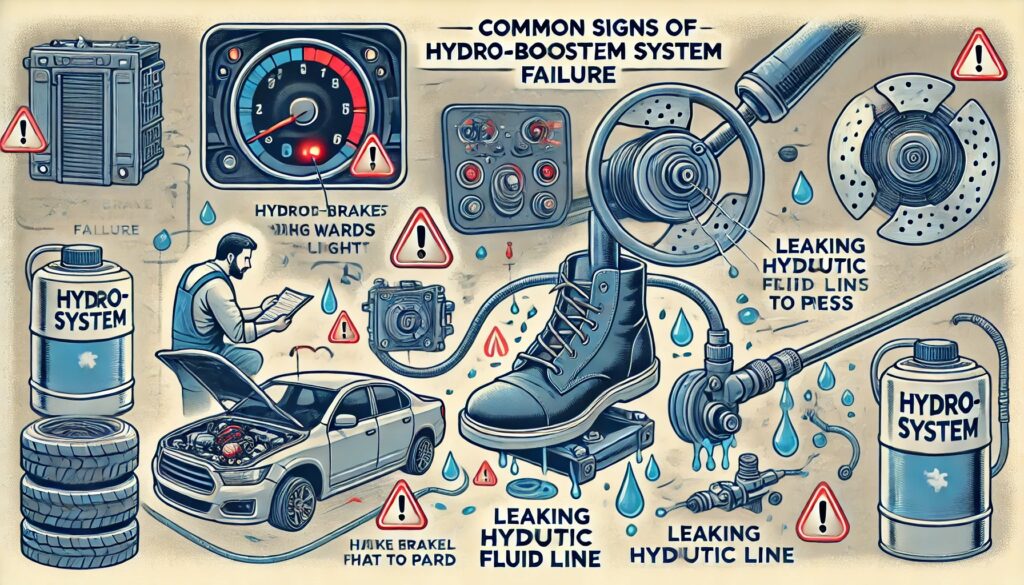

What Are Common Signs Of Hydro-Boost System Failure?

Common signs of Hydro-Boost system failure include several noticeable issues that can affect your vehicle’s braking performance. Here are the key symptoms explained in easy words:

Hard Brake Pedal

If you find it very difficult to press the brake pedal, this is a major sign of a failing Hydro-Boost. You should be able to press the pedal with moderate effort, but a hard pedal indicates that the system isn’t providing enough assistance.

Longer Stopping Distance

If your car takes longer to stop than usual, it could be due to a malfunctioning Hydro-Boost system. This happens because the system is not boosting the braking force effectively, making it harder to stop the vehicle quickly.

Engine Stalling

Sometimes, when you apply the brakes, the engine might stall or feel like it’s about to stall. This can happen if there’s a problem with the Hydro-Boost unit pulling too much vacuum from the engine.

Hissing Sound

If you hear a hissing noise when you press the brakes, it could mean there’s a leak in the Hydro-Boost system. This sound usually indicates that air is escaping from a damaged diaphragm or hose.

Fluid Leaks

Look for any hydraulic fluid leaks around the Hydro-Boost unit or power steering components. Leaking fluid can lead to reduced performance and eventual failure of the system.

Warning Lights

If your vehicle has warning lights on the dashboard related to the braking system (like ABS or brake warning lights), it could indicate an issue with the Hydro-Boost system.

Soft or Spongy Brake Pedal

A brake pedal that feels soft or spongy when pressed can also signal a problem with the Hydro-Boost. This means that the system may not be providing adequate pressure for effective braking.

Inconsistent Braking Feel

If you notice that sometimes your brakes feel firm and other times they feel weak, this inconsistency can point to issues within the Hydro-Boost system.

FAQs

1. Can the Hydro-Boost system work without engine vacuum?

Yes, the Hydro-Boost system is designed to function independently of engine vacuum, making it ideal for vehicles with low or no engine vacuum (e.g., supercharged or diesel engines). This ensures consistent braking performance in such situations.

2. What happens if the Hydro-Boost system has low hydraulic fluid?

If the Hydro-Boost system has low hydraulic fluid, it can lead to poor braking performance or hard brake pedal feel. It’s essential to regularly check the fluid level and top it off to prevent any potential issues with braking efficiency.

3. How can I tell if my power steering pump is causing problems with the Hydro-Boost system?

Signs of a faulty power steering pump affecting the Hydro-Boost system include strange noises from the pump, difficulty steering, or inconsistent braking power. If the pump isn’t providing enough pressure, it can prevent the Hydro-Boost system from working correctly.

4. Why is it important to use compatible components with the Hydro-Boost system?

Using incompatible components, like a higher-flow power steering pump or non-rated hoses, can lead to excessive pressure, causing damage to the Hydro-Boost unit and related parts. Always ensure that all components match the system’s specifications for safe and efficient operation.

Conclusion

The Ford Hydro-Boost system operates at 1,200 to 1,500 psi under normal conditions, with pressures reaching up to 2,500 psi during heavy braking. The pressure depends on the vehicle’s design and the power steering pump. Excessive pressure, often from an incompatible pump, can cause damage. Ensuring proper installation, compatibility, and regular maintenance (checking fluid levels and hoses) is key to maintaining optimal performance and avoiding failures.